Green Level

The OnLevelation begins.

Together for a sustainable future: OnLevel’s commitment to environmental responsibility and resource conservation.

Responsibility for our Earth and future generations.

OnLevel's environmental commitment

We all know that our world has limited resources, so it’s important to make responsible decisions in order to provide a good life on our beautiful planet for generations to come.

At OnLevel, we take this responsibility seriously. We use solar panels to meet our electricity needs, increasingly source our products locally (such as Kronos), and use recycled materials in both our products and packaging.

In addition, we work specifically with around 40 leading distributors in Europe to reduce transportation routes in the parcel sector. Our partners purchase larger quantities and are only periodically supplied, while regional distribution takes place directly from the customer’s warehouse.

We also rely on an extensive network for the procurement and processing of products to manufacture goods where they are needed.

Another focus is on working from home or in decentralized units to avoid unnecessary commuting resources.

At OnLevel, we continuously strive to minimize our ecological footprint and make a positive contribution to the environment.

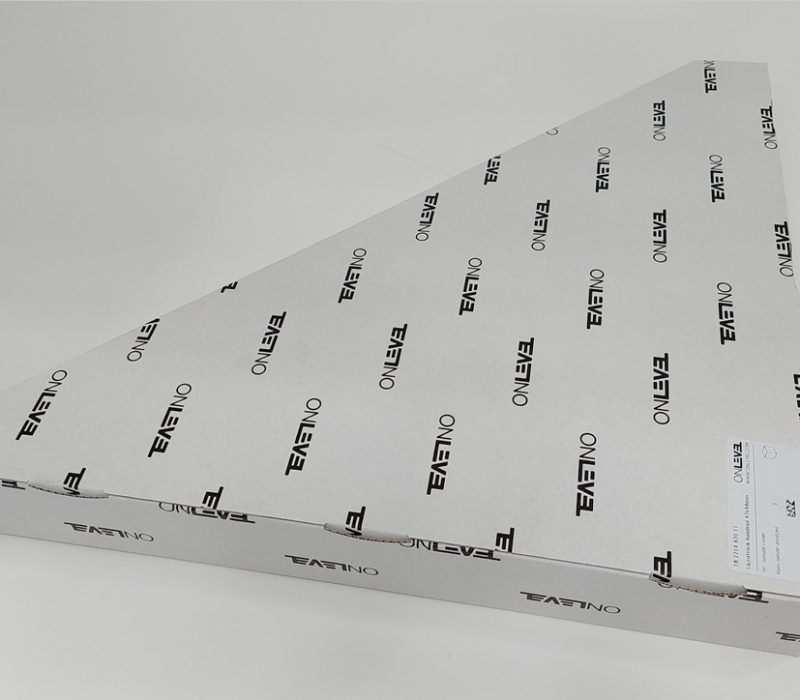

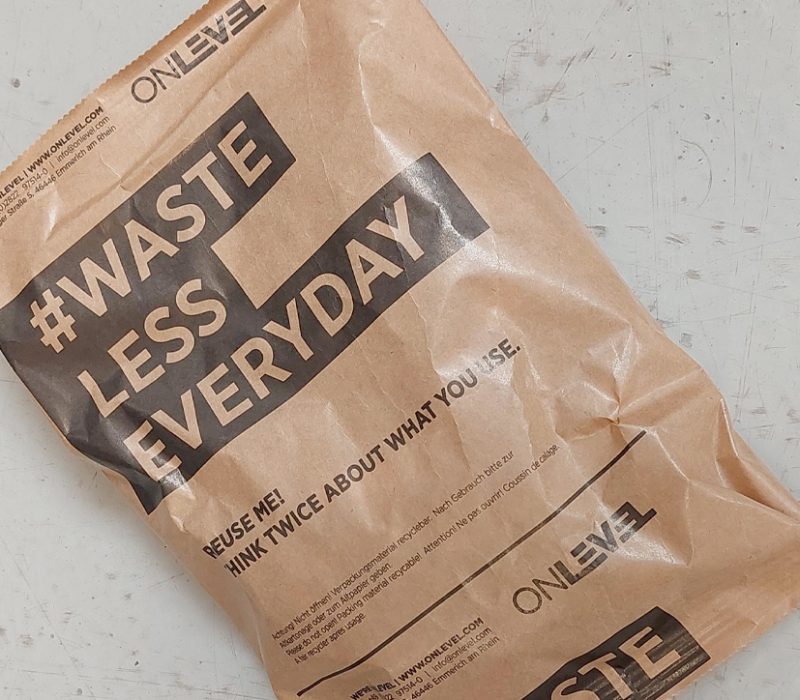

OnLevel has introduced various eco-friendly packaging solutions to minimize waste and reduce the use of plastic. They offer 15 different sizes of shipping boxes to ensure the contents fit optimally and leave as little empty space as possible. To fill any remaining space, they use recycled paper bags made from cardboard and paper waste, avoiding the use of plastic air cushions or bubble wrap.

For packaging large profiles, they use paper and tissue wraps instead of corrugated cardboard to reduce paper consumption and waste volume. These wraps also eliminate the need for additional foam or plastic to protect the surface of powder-coated profiles.

When transporting large TL profiles with additional items, OnLevel uses a robust double corrugated transport box with minimal wood usage, instead of a complete large wooden pallet box. Using this box, they can significantly reduce the need for plastic and foam. This transport box can also be used multiple times between their departments and by customers if they wish.

For larger items, we use cardboard boxes without adhesive or plastic tape. If packaging tape is necessary, it is made of paper, not plastic.

Additionally, we use cardboard tubes for transporting long covers or railings instead of plastic, foam, and tape.

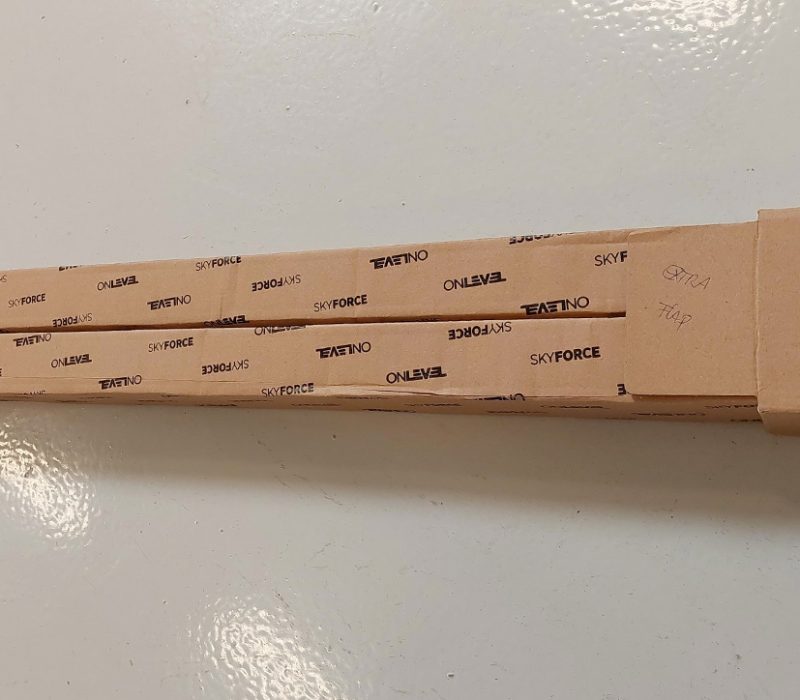

We have also developed a revised folding box for Skyforce that reduces waste volume and simplifies the packaging process. This new design allows for two profiles to be placed separately in one package and easily sealed using two folded cardboard end caps and some paper packaging tape.

By implementing these eco-friendly packaging solutions and optimizing our shipping boxes, we have achieved greater logistical efficiency. Our warehouse and AKL system benefit from this while reducing overall waste and space consumption.